About Us

ZHS 7th Gen Self-Loading Mixer with ±90° Rotation Boosts Engineering Efficiency

Views : 781

Update time : 2025-06-23 10:53:00

A technological revolution in construction machinery is quietly unfolding as Qingdao ZHS Machinery Co., Ltd. introduces its 7th generation self-loading concrete mixer. With globally unique ±90° rotating tank patent technology and integrated six-function design, the mixer redefines industry standards, bringing a one-stop solution for "loading-mixing-transporting-discharging-washing" to construction projects.

Core Technical Breakthrough: From "Single Mixing" to "All-in-One Operation"

The disruptive upgrade of the 7th generation product starts with the ±90° freely rotating concrete tank – this patented technology allows the equipment to discharge at any angle without dead corners, completely solving the pain points of residual material and angle limitation in traditional mixers. Meanwhile, the integrated "bucket down" function truly achieves five-in-one capabilities: loading, mixing, transporting, discharging, and car washing. One device can replace the collaboration of multiple traditional machines, boosting construction efficiency by over 60%.

Performance Advantages: Triple Guarantee of Safety, Durability, and Intelligence

- Military-Grade Hardware Configuration: Q345 manganese steel frame enhances load-bearing capacity by 3 times. Paired with 4×4 vacuum high-pressure tires (5 times more pressure-resistant than ordinary tires), it operates stably in complex terrains. The dual radiator independent cooling system ensures 24-hour continuous operation without overheating, while the hydraulic system uses a plunger motor and dual gear pump design for stronger power output.

- Intelligent Precision Control: Electronic scales monitor raw material ratios in real-time with an error ≤1%. The driving image system eliminates tank blind spots, and the aviation seat with a luxurious cab balances operational comfort and safety.

- Energy Saving and Maintenance Upgrade: Yuchai/Cummins diesel engines reduce fuel consumption by 20%. The high-pressure car washing pump and expanded water tank design maintain equipment cleanliness while reducing water waste, cutting maintenance costs by 40%.

Market Response: From Technological Innovation to Value Realization

"After our clients used ZHS mixers in African infrastructure projects, the construction period for a single project was shortened by 2 months, and the equipment failure rate was almost zero," revealed the ZHS Machinery Mr.zhang. The series has passed CE certification and is exported to over 50 countries. With a 120,000㎡ intelligent factory and 50 strict quality inspection processes, every device meets international standards upon delivery. From Southeast Asian bridge construction to domestic municipal projects, ZHS mixers are becoming the core equipment choice for global engineering firms with their "one-machine-multi-function" strength.

相关新闻

ZHS Wheel Loaders: Professional Quality, Factory-Direct Excellence

ZHS Wheel Loaders: Professional Quality, Factory-Direct Excellence

Aug 06,2025

ZHS factory is a professional manufacturer of wheel loader. Our Loader is equipped with comfortable luxurious seats, full hydraulic pilot control system and additional hydraulic operating lines. We Support Wholesale Price Purchases and OEM/ODM Service!

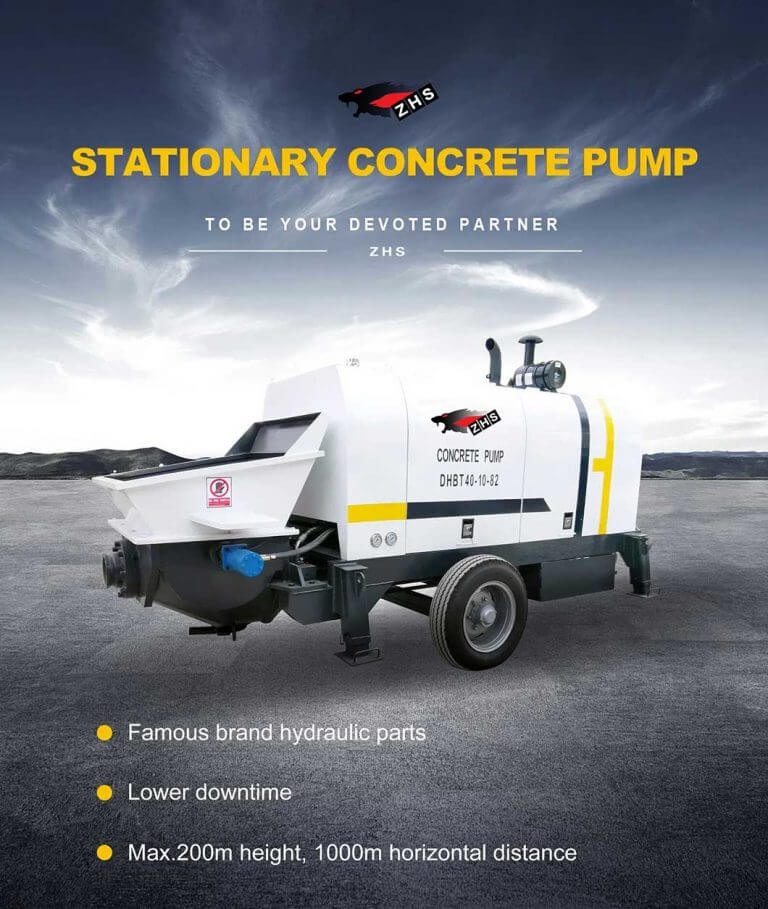

ZHS Trailer Concrete Pumps: Versatile Solutions for Every Construction Scenario

ZHS Trailer Concrete Pumps: Versatile Solutions for Every Construction Scenario

Jul 29,2025

ZHS Trailer Concrete Pumps, manufactured by Qingdao ZHS Machinery, feature top components like Kawasaki main oil pumps and Parker parts. Available in electric (3-phase power, low noise, zero emissions) and diesel (flexible, works with diesel) models, they cover 30-90m³/h capacities, with max 200m height and 1000m horizontal pumping. Used globally, they support wholesale and OEM/ODM services.

Mini Crawler Mixer: ZHS' Full-Hydraulic Dual-Function Gear Boosts Small-Space Efficiency

Mini Crawler Mixer: ZHS' Full-Hydraulic Dual-Function Gear Boosts Small-Space Efficiency

Jun 30,2025

ZHS has launched China's first patented mini crawler concrete mixer with full-hydraulic dual functions, suitable for small spaces and labor-saving, certified by CE.